This is an ongoing project, where we are supposed to convert rotary motion to linear motion and allow it to perform a simple task. for example, a machine that turns the pages of a book with linear motion but by the turn of a handle.

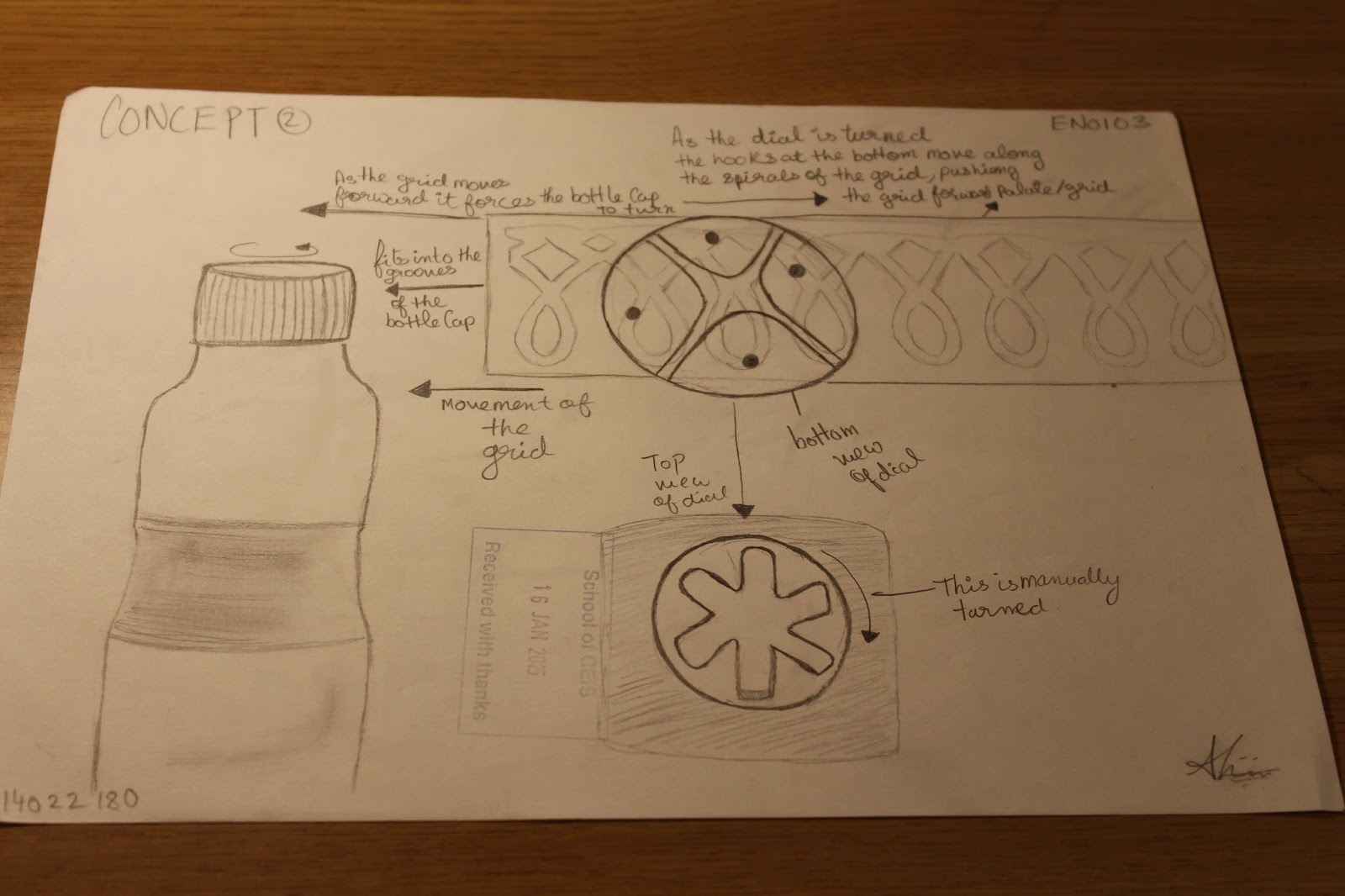

This design process, started with idea formulation and then the group used idea selection methods in order choose the final design. Out of a group of 4 each member listed three ideas, and then these ideas were critically analysed based no the design criteria, and finally the idea with the highest score was chosen. In this case it was my idea of a bottle top opener. Collectively as a group we improved the design, ordered the required parts and created a CAD model using Solidworks. The images below show the sketches and CAD drawings of the machine. (click image to enlarge)

BASIC DEIGN CONCEPTS

The basic idea is to turn a handle which turns gears which push out racks in a linear motion, unscrewing the top of the bottle.

INTEGRATED/DETAILED FINAL DESIGN

An image of the final and working machine will be uploaded once our group has finished building it.

- Ahana Kothari